Note

This kit is intended for educational and R&D use only, not for actual energy storage applications. That will happen later, check out our roadmap to see when.

Project homepage is at https://fbrc.dev, source code for this documentation is here.

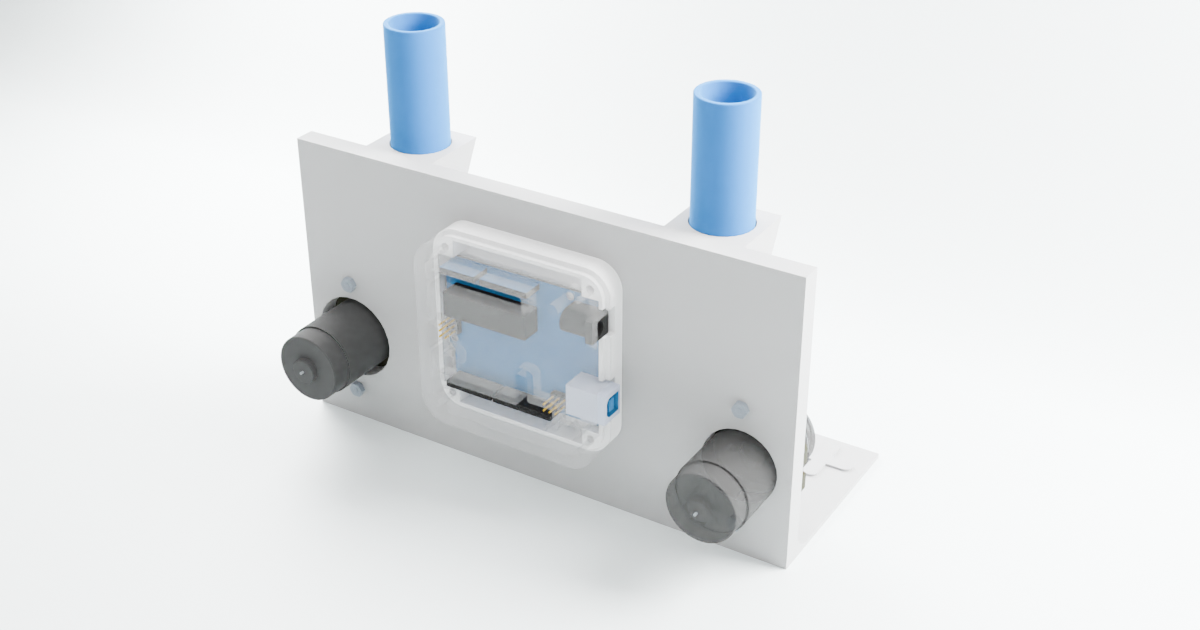

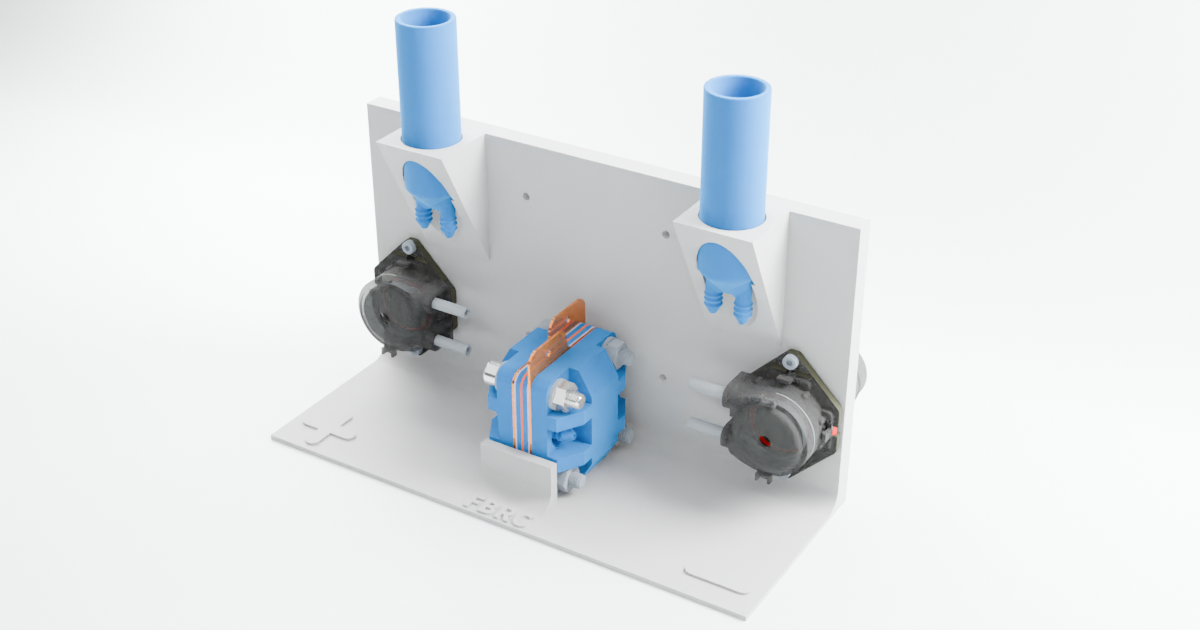

This bill of materials can be found here (![]() ,

, ![]() ).

).

If you're starting from scratch, you need to fabricate and source everything needed for using this flow battery test cell.

If you already have all the required components and materials, you can directly prepare the power electronics, assemble the cell, assemble the jig, prepare the electrolyte, and then begin testing. After an experiment, you should clean up your setup and analyze the data you obtained.

Video Guide

A video roughly showing steps 2-5 below is available here.